DEMINERALIZED WATER

Demineralized water is water low in dissolved solids, and has low electrical conductivity (measured in µS/cm).

ASTM D1193 Specification Standard for Reagent Type Water ( ASTM , American Society for Testing and Materials ),

classifies demineralized water as: “a water containing an electrical conductivity of less than 5 µS/cm.”

|

Type of demineralized water |

Electrical conductivity maximum permissible value ( µS/cm ) |

Typical application |

|

4. |

|

|

|

3. |

|

|

|

2. |

|

|

| 1. |

|

|

Completely the pure water is not a good electrical conductor,

however, In natural waters it contains various dissolved solids that provide ions with positive charges (cations) and negative charges (anions),

these ions present in the water allow the passage of electricity to through it.

The concentration of dissolved solids in water and electrical conductivity are directly proportional,

this means that increasing the concentration of dissolved solids increases conductivity.

The following table shows the most common cations and anions found in water.

| Cations (+) | Anions (-) |

| More common:

· Na + · Ca +2 · Mg +2

Others: · Faith +2 Faith +3 · Pb +2 · At +3 · Ba +2 |

More common:

· Cl – · HCO 3 – · CO 3 – · SO 4 -2 · PO 4 -2 · SiO 2 HSiO 3 – Others: · F – · H 3 AsO 3 |

What systems do I need to obtain demineralized water?

There are different processes to obtain demineralized water, in the industry the following can be found:

- Ion exchange

- Membrane filtration ( reverse osmosis)

- Distillation

- Electrodialysis

- Electrodeionization (EDI)

Demineralization using ion exchange resins.

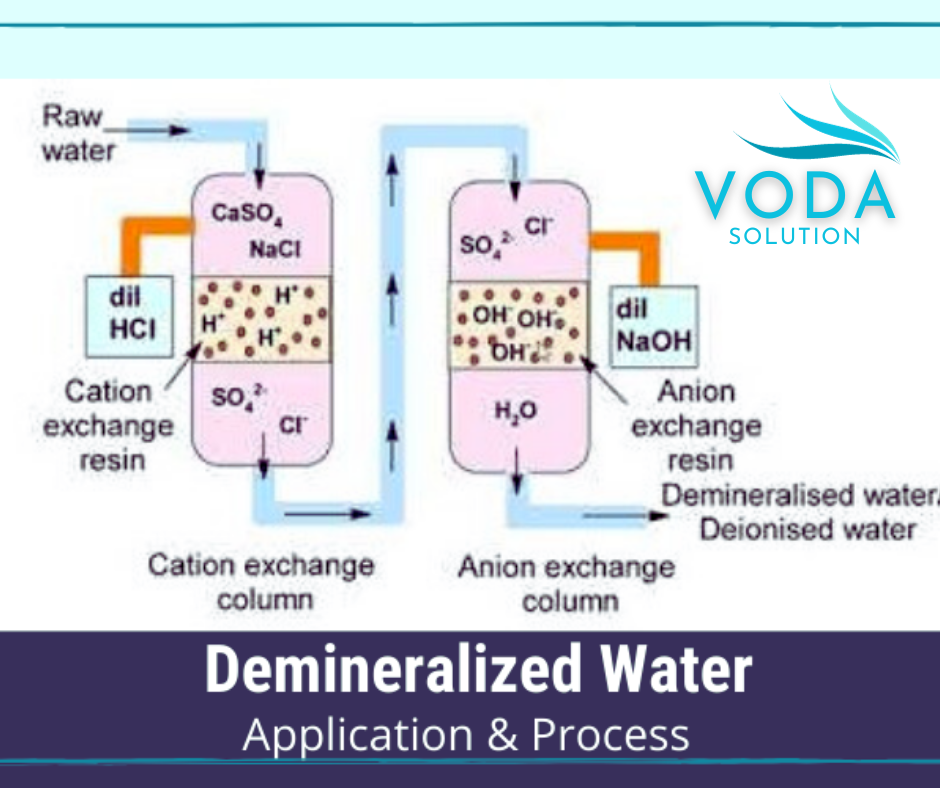

The water demineralization process by ion exchange consists of passing it through a bed of cationic resin (loaded with H+ ions) and an anionic resin (loaded with OH- ions), or a single bed with both (mixed resin).

Resins are classified into four main groups,

according to the bound functional groups that are attached to their polymer matrix, they are the following:

- Strong acid cation (SAC)

- Weak acid cation (WAC)

- Strong base anion (SBA)

- weak base anion (WBA)

The design of ion exchange systems will depend on the chemistry of the water (a complete study of anions and cations is recommended),

which determines the most effective combination of resins for a demineralization system.

Demineralization by reverse osmosis (RO).

Reverse osmosis consists of passing water through a semipermeable membrane at a high differential pressure (exceeding the osmotic pressure);

so that the dissolved solids are concentrated on one side of the membrane (rejection) and on the other side water with a low concentration of these (product).

The quality of the product water will depend on the feed and the specification of the percentage of salt rejection of the membrane.

RO systems allow different configurations to be designed, either to obtain better product water quality, to increase production volume or to reduce rejection volume.

Demineralization by distillation.

Demineralization by distillation is the chemical and biological purification of water through thermal vaporization and condensation.

Water distillation systems do not require too many controls on the feed water,

however, special care must be taken with the carryover of impurities and with variations in condensate quality.

Demineralization by electrodialysis.

Electrodialysis is a purification process, in which water is made to flow through cationic and anionic ion-selective membranes,

placed alternately, in a chamber called a battery or accumulator,

which supplies an electrical current for the flow of ions through through the membranes.

Ions are transported from a dilute solution to a concentrated solution.

Demineralization by Electrodeionization (EDI).

Electrodeionization (EDI) systems use a combination of resins,

ion-selective membranes and electrical charges to obtain water with a high degree of purity (up to 18.2 MΩ/cm) and that is also in continuous regeneration.

It consists of passing water through resin chambers delimited by ion-selective membranes.

The resin acts as a conductor allowing the electrical current to displace the anions and cations captured in the resin,

which are concentrated and expelled from the system in the rejection flow.

At the same time, the electric current separates the water into hydrogen (H + ) and hydroxyl (OH – ) ions,

that allow continuous regeneration of the resin without the need to use regenerating chemicals.

What are the benefits of demineralized water for your plant?

Demineralization is usually saved for uses where higher purity levels of water are required,

including process streams used in the manufacturing of electronics,

rinse water for the food and beverage industries, or feed or makeup water for high-pressure boilers.

The list of uses for demineralized water is not exhaustive because there are innumerable applications for it.

Nonetheless, it is an illustration of the most often used applications, separated out by industry:

Strength

Demineralized water is frequently utilized in the power sector for steam production and boiler feed water.

High-pressure boilers and, consequently, more sophisticated feed water treatment systems are needed for boilers

that produce steam to power turbines in order to remove as many contaminants as feasible.

The water particles gather and condense during the production of steam inside the boiler;

they are then recycled and utilized as boiler feed water.

Although the condensate produced by the steam-making process is technically distilled, dissolved gases like carbon dioxide and oxygen can occasionally be found in it.

On boiler pipes and parts, the chemical reactions brought on by the presence of these dissolved gasses can result in severe corrosion.

Usually, chemical scavengers, advanced deaeration equipment, or demineralization are used to eliminate these gasses.

Refinery

High-pressure boilers at refineries are fed with demineralized water, just like in the power industry.

Hardness and dissolved solids can seriously damage a facility’s machinery, and for the majority of high-pressure boilers and process streams, softening is frequently insufficient treatment.

The water treatment train usually includes demineralization by ion exchange or membrane filtration (mostly reverse osmosis or nano filtration),

as many higher-pressure boilers demand a higher quality of water with less pollutants than some lower-pressure boilers.

Chemical and petrochemical

High-purity boiler feed water is also necessary for the chemical and petrochemical sectors. Demineralization serves this purpose.

Cooling tower blowdown is another condition that can be treated with demineralization (which also applies to other industries mentioned).

In the event that your blowdown system’s water needs to be released, whatever discharge it produces must adhere to all applicable regulations.

Demineralization systems can assist reduce the cost of connecting to water and sewer lines,

which makes them a financially viable choice in locations where water is scarce and hefty sewer connection fees may apply.

If your wastewater is going to be released back into the environment or a publicly owned treatment works (POTW),

then the cooling tower bleed discharge also needs to comply with local municipal discharge requirements.

Food and Drink

Equipment and containers are frequently sanitized using demineralized water.

Although membrane filtration is often the method used to remove organic material, germs, viruses, etc., and it is also utilized in some food processing applications.

Demineralization is frequently a component of the entire water treatment process since the manufacture of food and beverages

must adhere to quality rules requiring ultrapure water at all stages of the manufacturing process.

Medications and Cosmetics

To ensure the quality and safety of their goods,

pharmaceutical and cosmetic manufacturers employ deionized and distilled water in their manufacturing processes.

Reverse osmosis or deionization are two separate processes,

however they produce demineralized water for various applications, cleaning, and rinsing, whereas recipes usually use distilled water.

Other Sectors

In many different industries, such as chemical production, mining, and electrocoating,

where it serves as a carrier for paint solids, demineralized water is employed for both cleaning and rinsing purposes.

It is also utilized in research labs to create a range of solutions.

Finicky post, finicky site, I give rise to bookmarked your blog, it truly is acceptable responsibility this. Say thanks.

THANK YOU FOR YOUR APPRECIATION.

Great solution for power plants an and dyeing industry.

This post says so much more info than other people, and it’s immensly helpful to me. Will be returning to read more writing from you! is it okay to share this?

thank you for your kind response.

cheers for the actual article i have recently been on the lookout with regard to this kind of advice on the net for sum time right now so many thanks

thanks you !

I think other website proprietors should take this site as an model, very clean and excellent user friendly style and design. As well as the content. You are an expert in this topic!

thank you !

I had a great stretch reading about your send as I read it extensively. Superlative calligraphy! I am looking disrespectful to hearing more from you

thank you for your kind response.

Great post. I was checking continuously this blog and I am impressed! Extremely helpful info particularly the last part I care for such info a lot. I was looking for this certain info for a long time. Thank you and best of luck.

Woah this is just an insane amount of information, must of taken ages to compile so thanx so much for just sharing it with all of us. If your ever in any need of related information, perhaps a bit of coaching, seduction techniques or just general tips, just check out my own site!

thank you for your kind response.

I found your blog site on google and examine a couple of of your early posts. Proceed to maintain up the very good operate. I just extra up your RSS feed to my MSN News Reader. Looking for forward to reading extra from you afterward!? I am often to running a blog and i really appreciate your content. The article has actually peaks my interest. I’m going to bookmark your website and preserve checking for brand new information.

thank you for your kind response.

This is a excellent blog, would you be involved in doing an interview about just how you designed it? If so e-mail me!

There may be noticeably a bundle to know about this. I assume you made sure good points in features also.

thank you for your kind response.

My brother recommended I might like this website. He was once entirely right. This publish actually made my day. You can not believe simply how much time I had spent for this information! Thanks!

thank you for your kind response.

Amazing! This blog looks just like my old one! It’s on a entirely different subject but it has pretty much the same layout and design. Wonderful choice of colors!

Wonderful blog! I found it while browsing on Yahoo News. Do you have any tips on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Many thanks

A formidable share, I just given this onto a colleague who was doing somewhat analysis on this. And he in actual fact bought me breakfast as a result of I found it for him.. smile. So let me reword that: Thnx for the deal with! However yeah Thnkx for spending the time to discuss this, I feel strongly about it and love reading more on this topic. If potential, as you become experience, would you mind updating your blog with more details? It’s highly useful for me. Big thumb up for this blog put up!

Wow, wonderful blog structure! How lengthy have you been running a blog for? you make running a blog look easy. The overall glance of your site is wonderful, as smartly as the content!

I think that is among the so much important information for me. And i’m satisfied studying your article. But wanna statement on some normal issues, The web site style is great, the articles is actually excellent : D. Just right process, cheers